The goal of this article is to explain chemical pump leaks in detail and provide useful solutions to not only solve current difficulties but also to implement long-term strategies for maintaining a seamless and efficient workflow.

How to fix chemical pump leakage problem

What are the most common reasons for a leaking pump?

Why do pump seals leak?

What amount of leakage is normal?

Here, you will find solutions to every problem associated with chemical pump leakage. So, let’s get started!

These are some common reasons for chemical pump leakage, including issues like inadequate installation, pump seal leaks, bearing wear, and fluctuations in pressure, among others.

Let’s delve into the details to understand this more comprehensively.

In the following sections, we offer comprehensive details to engage and guide you through the process of rectifying these concerns, ensuring an informative and captivating read.

INADEQUATE INSTALLATION

Proper installation is the key to the flawless performance of a mechanical seal. Ensuring meticulous installation not only enhances efficiency but also acts as a safeguard against potential leaks, ensuring the longevity of your pump system.

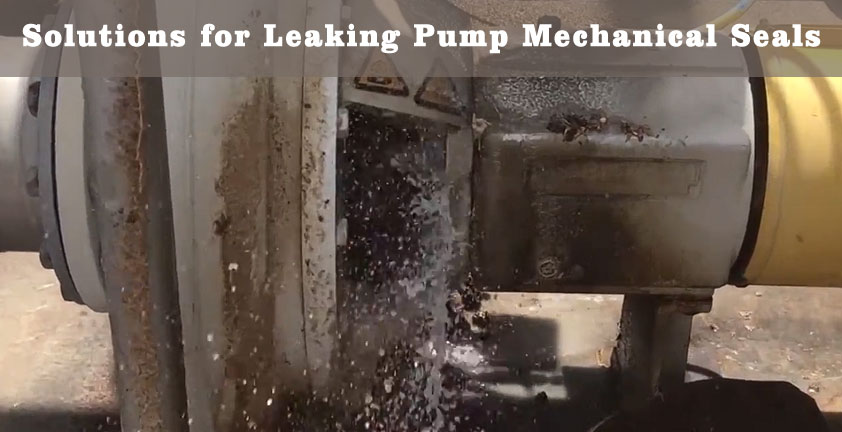

MECHANICAL SEALS LEAKS

The predominant factor contributing to chemical pump leakage stems from the malfunction of mechanical seals. In the event of pump leakage, a crucial initial step involves a thorough examination of the mechanical seal. The key to mitigating this issue lies in the meticulous use of high-quality mechanical seals and precise installation procedures, offering a potential reduction of up to 90% in pump leakage problems.

BEARING WEAR

The occurrence of leakage in chemical pumps is often attributed to the breakdown or failure of bearings. Prolonged use of mechanical seals without regular servicing and the use of subpar quality bearings can frequently result in leaks from the pump’s mechanical seals. To ensure optimal performance and prevent such issues, it is imperative to employ high-quality bearings and adhere to regular maintenance practices for mechanical seals.

FLUCTUATIONS IN PRESSURE

Inadequate pump pressure could signal a potential malfunction in the mechanical seal, posing a risk of pump leakage. It is crucial to address and rectify this issue promptly to maintain optimal performance and prevent any operational disruptions.

Safeguard your Chemical Pump from potential leaks by choosing top-notch, ISO-certified mechanical seals like Microseals—an industry-leading brand in manufacturing.

Properly installing the mechanical seal is crucial; steer clear of dry running to prevent heat-induced damage. For a Dual Cartridge Mechanical Seal to counter dry running effectively. Consistent upkeep, including storing the seal in optimal temperatures and regular servicing, not only ensures longevity but significantly diminishes the risk of pump leakage over time.

Elevate your pump’s reliability with our premium solutions, designed for lasting performance and peace of mind.

To Know More About Mechanical Seals Service Read Our Blog Post on Mechanical Seal Face Materials for Abrasive Services or For More General Slurring Pumping Information, Check Out Our Slurry Mechanical Seals Product.

Microseals Is ISO 9001:2015 Certified Company and Leading Mechanical Seals Manufacturer & Supplier In India, Providing Leakages Solutions To All Types Of Pump Applications By Manufacturing Mechanical Seals And Sealing Components As Per Customer’s Require, Samples or Need. To Know More About Mechanical Seal Call On +91 – 9029035767 Or Email At [email protected]