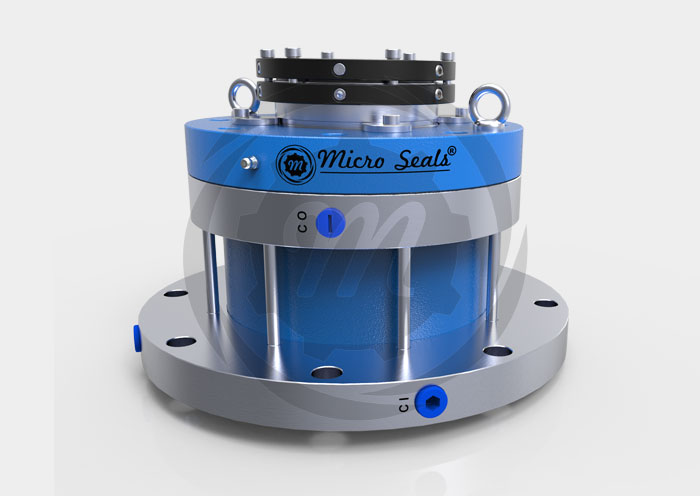

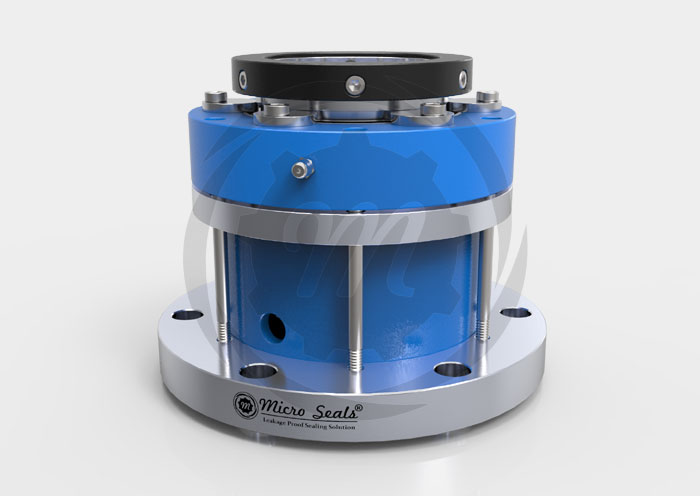

DOUBLE MECHANICAL SEALS

W58/W59B Is A Dual-Pressurized, Liquid-Lubricated Cartridge Seal For Glass-Lined Mixing And Agitating Equipment With Vertical Type Agitation Equipment.

Double mechanical seals are designed to maximum secure sealing safety. These seals virtually stop leakage of the fluid or gas being handled in pumps or mixers. A double mechanical seal has two primary seals with a barrier or buffer fluid area in between. Each primary seal typically consists of a softer, narrower stationary face accompanied by a harder, wider rotating face. This arrangement enables the softer seal to wear while maintaining the integrity of the harder faced seal during service. This is essential when pumping or mixing a dangerous or toxic substance.

Multi Spring Double Mechanical Seal

Double mechanical seals are multi spring double mechanical seal design where absolute leak proof sealing is necessary due to toxic, hazardous nature of fluid.

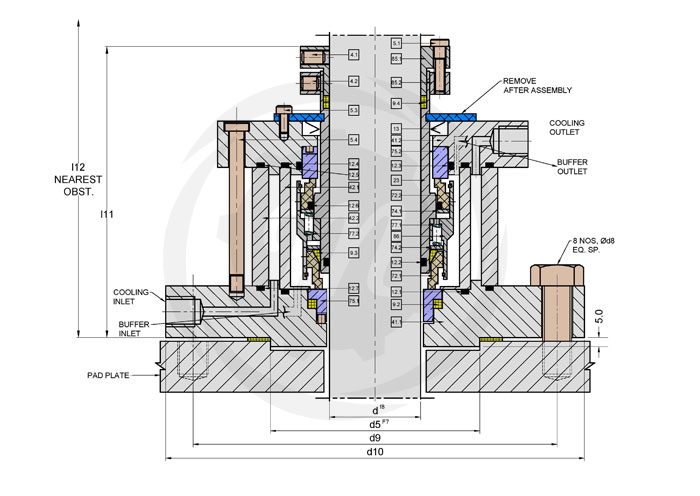

Double Mechanical seals is a combination of two conventional seals installed back to back inside stuffing box.

The inner seal prevents the circulated fluid to enter the system and the outer seal prevents it from leaking it to atmosphere. The circulation of the fluid reduces the heat generated on the seal faces.

- For top entry drives

- Glass Lined Reactor Or Agitators

- Double seals

- Unbalanced Seal mechanism

- Independent of direction of rotation

- Multiple springs rotating

- Liquid-lubricated

- Cooling provision with jacketing

- With and without bearing

| Seal Ring Face | : Carbon, Silicon, TC |

| Mating Ring Face | : Silicon, TC |

| Secondary Seals | : Viton/PTFE/GFT |

| Metal Parts | : SS 316, Alloy 20, 904L |

| Pressure | : 10 bars (Max) |

| Temperature | : (-)50c to (+)280c |

| Speed | : 2900 rpm (Max) |

| Size | : 16 mm to 150 mm |

- Petrochemicals

- Petro Refinery

- General Chemicals

- High temperature pumps.

| Item No | |

|---|---|

| 1 | |

| 2 | |

| 5 | |

| 6 | |

| 7.1 | |

| 12 | |

| 13 | |

| 19 |