A Mechanical Seal Is A Piece Of Common And Incredible Sealing Technology. From The Simplest Applications Of The Most Difficult Situations, The Design Is Designed To Reliably Prevent Rotation Leakage Goods. A Single Design Can’t Possibly Address Every Set Of Conditions And Many Applications That Exist. Relying On Experts That Develop The Design And Materials Used In Mechanical Seals Is Often The Most Careful Approach To Extracting The Best Value. The Face Is One Of The Two Most Important Components Of Mechanical Seals.

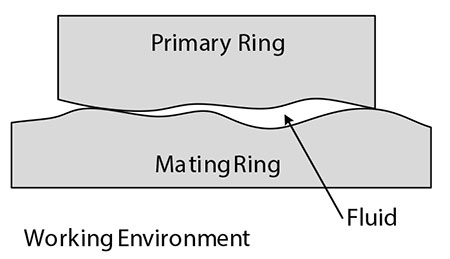

Primary Ring and Mating Ring

- These Components Ensure Proper Functioning

- These Faces Are Highly Designed In Terms Of Layout And Materials Used.

- The Interface Between The Primary And Mating Ring Is Where Fluid Lubrication Is Critical For Providing Low Leakage.

- A Variety Of Mating Ring Materials Are Regularly Employed

- It Is Important To Use The Option That Provides The Best Value For The Application

- Oxide Ceramics (Alumina)

- Coated Metals

- Cemented Carbides (Tungsten Carbide)

- Nonoxide Ceramics (Silicon Carbide)

- Diamond-Coated Nonoxides.

Sealing Sense

These Materials Combined Properties, Combined With Proprietary Machining Techniques, To Provide Consistently Unique And Controlled Surface Visibility That Enables:

- Briefly Manage Surface Roughness To Increase Fluid Present At The Interface

- Promote Thermal Conductivity To Effectively Transfer The Generated Friction Heat Away From The Interface

- High Hardness To Efficiently Pulverize Any Solids That Tend To Come Out Of Solution Near That Interface

- Minimal Tendency To Trap Those Abrasives at The Interface

Microseals Is ISO 9001:2015 Certified Company and Leading Mechanical Seals Manufacturer & Supplier In India, Providing Leakages Solutions To All Types Of Pump Applications By Manufacturing Mechanical Seals And Sealing Components As Per Customer’s Require, Samples or Need. To Know More About Mechanical Seal Call On +91 – 9029035767 Or Email At [email protected]