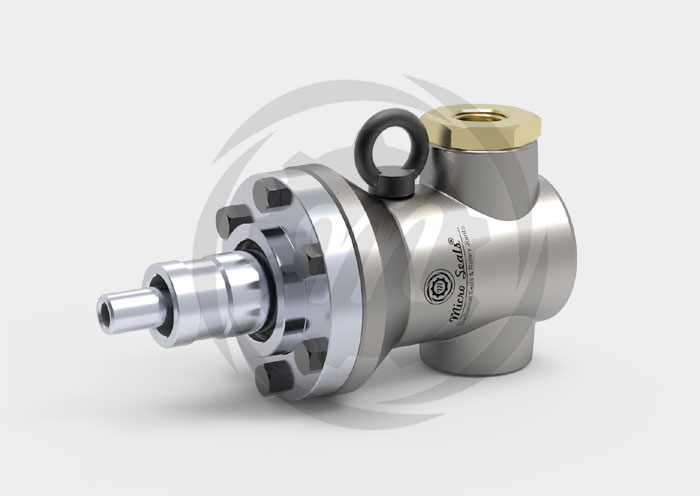

Rotary Joint for Steam Application

Micro Seals steam rotary joints features carbon bearings to add strength and shock resistance assuring a long service life and reduced maintenance. The seal wear indicator allows for planned maintenance reducing downtime and increasing productivity for water applications.

A convex seal ring to withstand mechanical and thermal shock to extend the union’s service life. The steam rotary joints can a stationary or rotating siphon to accommodate any corrugating machine. Steam rotary joints for cooling systems are designed to reduce sheet temperature uniformly for a quality product.

It features a self-supported design and bush bearings for the rotor to rotate in the joint body. The featured balanced mechanical seals extend service life and reduce the pressure and torque. Micro Seals steam rotary joints are made of 316 stainless, C.I Nickel plated steel to resist corrosion even in high-temperature environments.

Steam and Hot Oil Service Rotary Joints

Rotary Joints Suitable For Hot Water, Steam and Hot Oil Service

- Monoflow and dualflow design

- Self-supported rotating union

- Radial housing connection

- Balanced mechanical seals

- Easy and quick replacement of sealing components

- Keyed rotor seal

High Temperature Steam Rotary Joints

Steam and Hot Oil Rotary Joints For High Temperature Steam Applications

- Monoflow and dualflow design

- Self-supported rotating union

- Radial or Axial housing connection

- Balanced mechanical seals

- Easy and quick replacement of sealing components

General Purpose Rotary Joints For Steam Hot Water Service

General Purpose Rotary Joints For Steam Hot Water Service

High Temperature Steam Hot Oil Rotary Joints

High Temperature Steam Hot Oil Rotary Joints